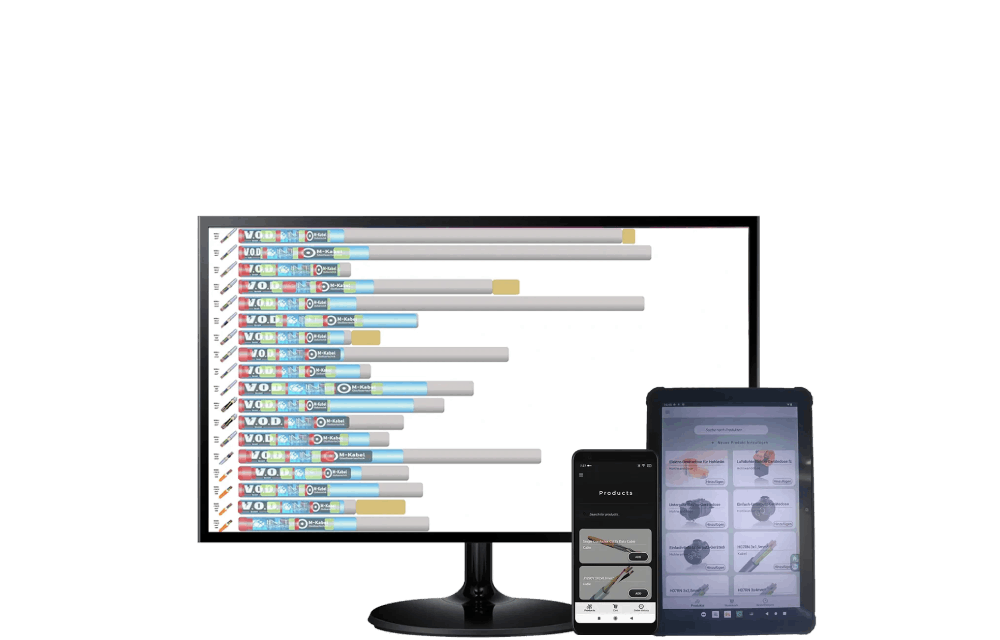

Digital Warehouse

Centralized recording of materials, tools, and equipment – in real time, without duplicate entries and without losses.

The Aprolitic Digital Warehouse connects goods receipt, storage, issue, intermediate storage, and installation into a seamless data flow. Everything is seamlessly traceable from goods receipt to installation, with a clear change log (audit trail) for every adjustment.

Key benefits

- Significantly fewer losses: mandatory digital handovers and clear accountability by person/team.

- Faster issuing & returns: less waiting, fewer work interruptions, fewer “missing” items.

- Anytime transparency: stock by location / zone / distribution board (panel); who took what and when.

- Procurement optimization: min/max thresholds, automatic notifications, replenishment planning.

- Reduced write-offs & overstock: controlled returns, recording of cable remnants and waste.

How it works (end-to-end)

- Receiving Recording of batch/lot, quantity and location.

- Storage - place by locations and intermediate warehouses with clear mapping.

- Issuing - by work order / zone / board / team; automatic pick lists and digital handovers.

- Installation / Returns – Verbuchung verbauter Materialien, Rückgabe wiederverwendbarer Teile, Abfallerfaßung.

- Stocktaking - fast scan-based checks; one-click plan vs. actual variance.

Capabilities

- Materialstammdaten: EAN, batch/lot, expiry dates, substitute items, units of measure.

- Intermediate storage & transfers: controlled internal moves with a complete trace.

- Cable remnants & waste: precise, verifiable recording.

- Roles & permissions: warehouse clerk, Bauleiter (site manager), project manager — each sees and does exactly what’s needed.

- Offline mode: Local on-site capture, secure synchronization after connection is restored.

Reporting & integrations

- Exports: Excel (standard) and PDF reports— ready for supervision/clients.

- Live stock view: the status of every material is visible in real time in the web app.